Automatic Material Roll Changes

The 90-2 model has a second head for true Zero-Downtime, On-the-Fly Reel Changes. When one reel of material is finished, the second head shuttles into place and begins feeding a new roll while the machine is running at full speed. No operator intervention required!

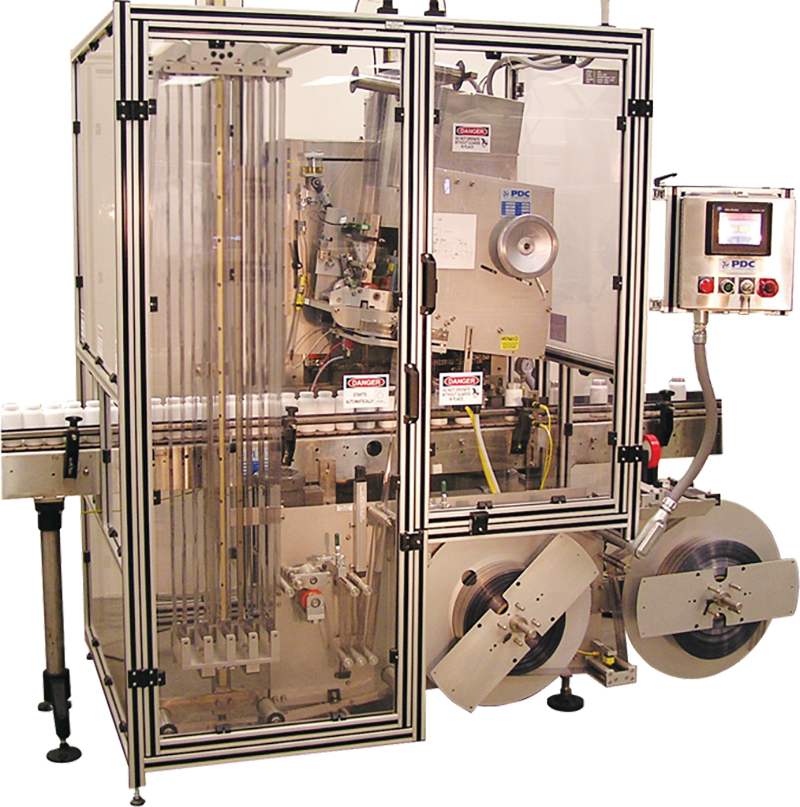

Combining true “24/7” operation with high speeds and true “zero downtime” performance, the PDC Series 90 Shrink Sealers are engineered for highest OEE* rankings in all 3 categories: uptime, performance, and quality of product produced.

Applications of the 75 and 90 Series include:

Tamper Evident Banding:

- Neckbanding – applying a shrink sleeve around the upper portion of a container and its closure

- Full Height Safety Seals – full body, clear sleeves, protecting the paper label, container and covering the closure (as on some vitamin jars)

Shrink sleeve Labeling:

- Full height body sleeve labels – on bottles and jars providing primary package graphics. The sleeve label may also come up over the cap with a horizontal perforation for tamper evidence.

Standard Features

- A Full Array Of Sensors

- Allen-Bradley PLC

- NEMA 4 Electrical Enclosures

- Servo Feed Drive (90 Series)

- Stainless Steel Frame and Covers

Optional Features

- 2D and Barcode Scanners

- Automatic Reel Changeover (eliminating downtime)

- Band Cut Off Registration

- Vision and Band Inspection/Ejection Systems

- Shrink Tunnels